Temperature, It sounds simple. Just heat and cold. But inside an industrial plant, temperature decides everything. Product quality. Safety. Efficiency. Even downtime. One wrong reading, and things spiral. This is where a temperature transmitter quietly does its job. You may not see it. You may not think about it. But it works. All the time. This guide walks you through what a temperature transmitter really is, how it works, why industries rely on it, and how choosing the right partner, like RBA OPTISYNC PRIVATE LIMITED makes a real difference. Stay with it. This one matters.

What Is a Temperature Transmitter

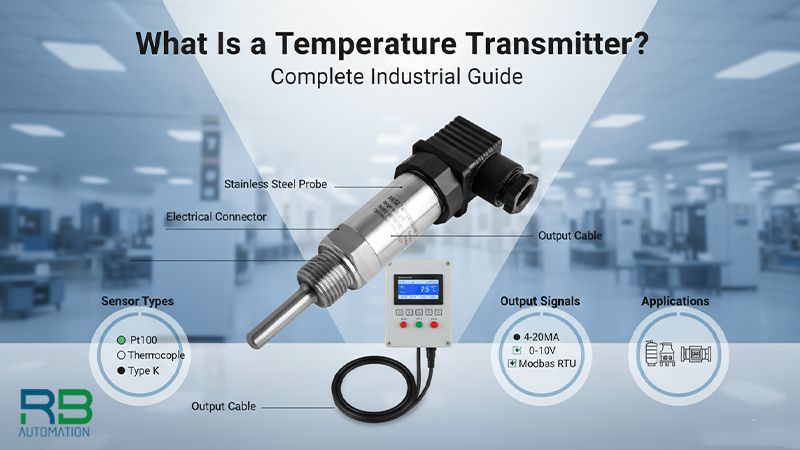

A temperature transmitter is basically the translator of the industrial world. It takes raw temperature readings and turns them into clean, standardized signals. Usually 4–20 mA. Sometimes digital. Either way, control systems can understand it.

Sensors like RTDs or thermocouples do the sensing part. That’s their job. But on their own, those signals are messy. Too weak. Too raw. The transmitter steps in and makes them usable. Simple idea. Big impact.

In factories, power plants, chemical units, and food processing lines, temperature isn’t a “rough estimate” thing. It must be right. Every time. One wrong reading and things go south fast. That’s why industries rely on proper transmitters. Not assumptions. Not guesswork. Just solid, reliable data.

Why Temperature Measurement Is Critical in Industries

Temperature affects chemical reactions, mechanical strength, fluid viscosity, and electrical performance. Too hot. Too cold. Both cause damage. A stable temperature process keeps machines healthy and products consistent. Industries using temperature transmitter systems gain real-time monitoring, fewer errors, and better process control. This is not optional anymore. It’s standard practice.

How a Temperature Transmitter Works

The process starts at the sensor. RTDs or thermocouples detect temperature changes. The transmitter receives this signal. It conditions it. Amplifies it. Filters noise. Then outputs a clean, standardized signal to PLCs, DCS, or SCADA systems. Operators see real numbers. Controllers respond instantly. That’s the loop. Quiet. Fast. Reliable.

Types of Temperature Transmitters

Industrial applications demand flexibility. Different processes need different transmitters. Common types include:

- Head-mounted transmitters used inside sensor heads for compact installations.

- Rail-mounted transmitters installed inside control panels for easy maintenance.

- Field-mounted transmitters designed for harsh environments.

- Contact temperature transmitter units that directly touch the measurement surface for accurate readings.

Each type serves a specific purpose. Choosing wrong causes errors. Choosing right improves control.

Understanding Contact Temperature Transmitters

A contact temperature transmitter measures temperature by physical contact with the object or medium. No guessing. No infrared drift. Just direct measurement. These transmitters are widely used in pipelines, tanks, reactors, and machinery surfaces. When accuracy and stability matter, contact measurement wins. Many industries prefer working with a trusted contact temperature transmitter supplier who understands application needs instead of just selling hardware.

Where Contact Temperature Transmitters Are Used

These transmitters are everywhere. Oil and gas pipelines. Pharmaceutical reactors. Food processing equipment. HVAC systems. Power plants. Plastics and rubber manufacturing. Anywhere surface or process temperature drives outcomes. Industries looking for dependable Temperature Transmitter Suppliers in India often focus on contact transmitters because they deliver consistent results over long operating cycles.

Key Benefits of Using Temperature Transmitters

Temperature transmitters offer practical benefits that go beyond numbers:

- Stable signal transmission over long distances.

- Reduced electrical noise and signal loss.

- Better accuracy compared to raw sensor outputs.

- Easier integration with automation systems.

- Improved safety and process reliability.

These benefits explain why modern automation depends on the temperature transmitter as a core component.

Selection Factors That Actually Matter

Choosing a transmitter is not about price alone. It’s about fit. Consider the process temperature range. Sensor compatibility. Environmental conditions. Mounting style. Output signal type. Calibration needs. Long-term stability. When working with Temperature Transmitter Suppliers in India, technical support and product reliability should guide decisions, not shortcuts.

Role of Calibration and Accuracy

Even the best transmitter needs calibration. Over time, sensors drift. Calibration keeps readings honest. Industries that skip this step face product variation and safety risks. Reliable suppliers guide calibration schedules and support maintenance planning. A good contact temperature transmitter supplier treats accuracy as a responsibility, not a feature.

Industrial Automation and Temperature Control

Automation systems depend on data. Bad data breaks logic. Good data builds trust. Temperature transmitters feed control loops that regulate heaters, coolers, valves, and alarms. Without them, automation becomes blind. This is why system designers prioritize proven temperature transmitter solutions over experimental ones.

Challenges Without Proper Temperature Transmitters

No transmitter means unstable signals. Noise interference. Manual readings. Delayed responses. In critical industries, these gaps cause production losses and safety incidents. Using industrial-grade transmitters solves these problems quietly, day after day.

Why Indian Industries Demand Quality Suppliers

India’s industrial growth demands robust automation hardware. Harsh climates. Continuous operations. Tight margins. All require dependable partners. That’s why companies search specifically for experienced Temperature Transmitter Suppliers in India who understand real operating conditions, not just catalogues.

RBA OPTISYNC PRIVATE LIMITED and Industrial Temperature Solutions

RBA OPTISYNC PRIVATE LIMITED focuses on practical, application-driven automation products. The company supports industries with reliable temperature measurement solutions designed for accuracy and durability. RBA OPTISYNC PRIVATE LIMITED works closely with clients to match the right temperature transmitter to the right process. This approach builds trust. Over time. Project after project.

Why Choose Us

RBA OPTISYNC PRIVATE LIMITED stands out for one simple reason. The focus stays on your application. Not just the product on paper. The team understands how temperature really behaves on the shop floor. Heat spikes. Noise. Harsh conditions. And how even small measurement errors quietly turn into big operational problems. That experience shows. By offering reliable solutions, quick support, and guidance that’s practical, they become more than a supplier. Much more. They become a technical partner. Someone who helps your systems stay stable. Safe. Efficient. Even when conditions get tough. And in industrial environments, they often do.

Conclusion

Temperature control quietly decides whether an industry runs smoothly or constantly fights fires. Most people don’t notice it. Engineers do. A well-chosen temperature transmitter brings calm to the chaos. Stable processes. Safer operations. More confidence on the floor.

From simple monitoring to high-level automation, transmitters turn raw temperature into something useful. Something systems can act on. That’s where the real value sits. Not in numbers alone, but in what those numbers do. Understanding transmitter types, applications, and selection factors makes a difference. It helps protect equipment. Improves output. Reduces surprises. And surprises are expensive.

Working with experienced suppliers like RBA OPTISYNC PRIVATE LIMITED adds another layer of reliability. Technical knowledge meets real-world conditions. No theory-only solutions here. When temperature data is accurate, systems respond better. Products stay consistent. Operations stay in control. In industrial environments, that balance matters. Every single day.

Want expert guidance on choosing the right temperature transmitter for your process? Call us at +91 8511104864 or email contact@rbautomate.com for detailed technical support and product information.

Key Takeaways

- A temperature transmitter does more than measure. It converts raw sensor data into signals your control system can use.

- Contact temperature transmitter solutions bring stability and accuracy, especially where consistency isn’t optional.

- The supplier you choose today shows up in performance tomorrow. And in safety. Long-term.

- Industrial automation runs on good data. Bad temperature readings quietly break everything downstream.

- RBA OPTISYNC PRIVATE LIMITED focuses on application-driven temperature solutions, not one-size-fits-all products.

FAQs

What is the main function of a temperature transmitter?

Think of it as a translator. It takes raw signals from temperature sensors and converts them into clean, standardised outputs that control systems can trust. The result Better accuracy. More stable signals. Fewer surprises.

Why use a contact temperature transmitter?

Because direct contact removes guesswork. When the sensor touches the process, readings stay consistent and reliable. That matters in real industrial conditions, not just on paper.

How do I select the right temperature transmitter?

Start with your process. Temperature range, operating environment, sensor type, and system compatibility all matter. Miss one detail, and performance suffers later.

Are temperature transmitters suitable for harsh environments?

Yes. Industrial-grade transmitters are built for it. Vibration, heat, electrical noise—they’re designed to keep working when conditions get rough.

Why choose RBA OPTISYNC PRIVATE LIMITED?

Because the focus stays on application-first solutions. Strong technical support. And long-term reliability that doesn’t fade after installation.