You know that moment when a tank looks calm on the outside, but inside the numbers keep shifting. Quietly. Relentlessly. That’s where measurement either works…or fails you. Continuous level measurement is not a luxury anymore. It’s the backbone of process control. And this is exactly why industries lean toward hydrostatic level sensor technology. Simple in concept. Powerful in real life. Trusted where accuracy matters.

At RBA OPTISYNC PRIVATE LIMITED, we see this every day. Plants running nonstop. Fluids changing density. Conditions never staying still. The solution must be stable. Predictable. Honest. That’s what hydrostatic measurement brings to the table.

Understanding the Principle Behind Hydrostatic Level Measurement

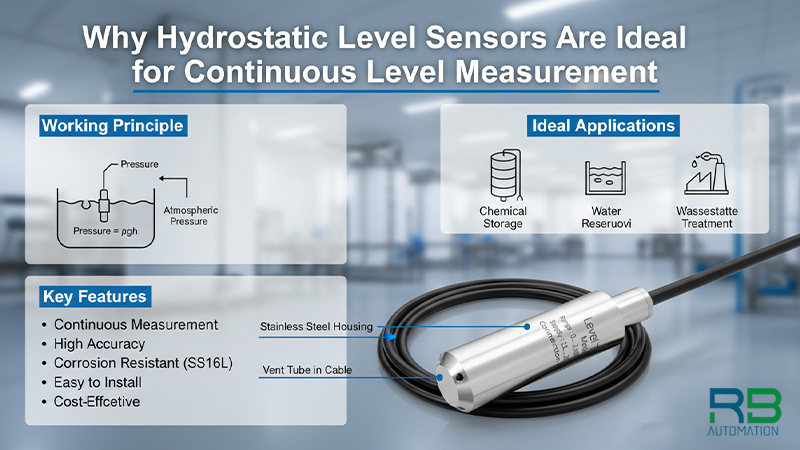

At its core, hydrostatic measurement follows physics that never argues back. The pressure at the bottom of a liquid column directly relates to the height of that liquid. No moving parts guessing. No complex calculations pretending to help. A hydrostatic pressure sensor measures the pressure exerted by the liquid. That pressure converts into an accurate level reading. Clean. Direct. Reliable.

This is why hydrostatic pressure level sensors perform so well in continuous measurement applications. They don’t depend on surface conditions. Foam, vapours, agitation. None of that distracts them. The sensor stays focused on what matters. The pressure below.

Why Continuous Level Measurement Needs a Different Approach

Continuous measurement is not about checkpoints. It’s about flow. Processes don’t pause so your sensor can catch up. You need live data. Constant feedback. That’s where a hydrostatic level transmitter proves its worth. It sends a continuous signal that reflects real-time level changes. No guessing. No delays.

Unlike point-level devices, hydrostatic level transmitters stay active across the entire measurement range. Whether the tank is nearly empty or close to full, accuracy stays consistent. That consistency protects operations. It protects equipment. It protects decisions.

Built for Real Industrial Conditions

Factories are not gentle places. Temperature shifts. Chemical exposure. Vibrations that never stop. A hydrostatic water level sensor is designed for this reality. Submersible. Sealed. Tough. It sits inside the liquid and keeps working.

This design reduces mechanical wear and removes common failure points. No floats getting stuck. No ultrasonic waves getting confused. Just direct pressure measurement doing its job. Over time, this means fewer breakdowns and lower maintenance demands.

Accuracy That Doesn’t Drift with Time

Accuracy is not just about today. It’s about next year too. Hydrostatic sensors maintain stability because their measurement principle does not degrade easily. When calibrated correctly, a hydrostatic level sensor delivers repeatable readings over long periods. This matters in industries like water treatment, chemicals, oil storage, and food processing. Processes depend on trends, not just numbers. Reliable trends come from sensors that don’t wander.

Installation That Makes Sense

Another reason industries prefer hydrostatic level transmitters is installation simplicity. There’s no need for complex alignment or structural modifications. The sensor is installed at the bottom of the tank or vessel. That’s it.

For deep tanks, narrow wells, or underground reservoirs, a hydrostatic pressure sensor fits naturally. This flexibility saves time during setup and avoids unnecessary downtime.

Adaptable Across Multiple Applications

From clean water to aggressive chemicals, hydrostatic technology adapts well. With appropriate materials and housing, hydrostatic pressure level sensors can handle a wide range of media. This adaptability makes them ideal for industries that manage multiple liquids across different processes. One measurement principle. Many applications. Less complexity in system design.

Signal Stability and Process Integration

Modern hydrostatic level transmitter designs integrate smoothly with PLCs, SCADA systems, and control panels. Output signals remain stable even in electrically noisy environments.

For automation teams, this stability reduces false alarms and data inconsistencies. For management, it means confidence in reports and dashboards. Data tells the truth. Every time.

Long-Term Cost Benefits

While initial selection matters, long-term cost tells the real story. Hydrostatic level sensor systems reduce maintenance, minimize downtime, and lower replacement frequency. Over years of operation, these savings add up quietly but significantly. This is one of the reasons RBA OPTISYNC PRIVATE LIMITED continues to recommend hydrostatic solutions for continuous measurement projects across industries.

Why Industries Trust Hydrostatic Measurement

Trust builds when systems don’t surprise you. When readings match reality. When alarms trigger only when needed. Hydrostatic level transmitters earn that trust through consistency. They don’t rely on guesswork. They rely on pressure. Physics doesn’t negotiate. And that’s exactly what industrial environments need.

Why Choose Us

Choosing RBA OPTISYNC PRIVATE LIMITED means choosing experience that translates into practical solutions, not theoretical promises. We focus on application understanding, correct sensor selection, and reliable implementation so your measurement system works smoothly from day one. Our approach stays grounded in real operating conditions, long-term performance, and honest technical guidance. We don’t oversell features. We align solutions with your process needs. That’s why clients return, project after project, trusting RBA OPTISYNC PRIVATE LIMITED to deliver dependable hydrostatic level measurement solutions that quietly support their operations every single day.

Conclusion

Continuous level measurement doesn’t forgive mistakes. It needs accuracy, stability, and reliability—all the time. No shortcuts. That’s where hydrostatic level sensors quietly prove their value. They work on a simple, pressure-based principle. Solid physics. No guessing. Surface foam, vapor, turbulence, environmental noise—none of that throws them off. They just keep measuring. Calmly. Consistently. What really makes them stand out is the reliability of real-time data. The readings stay steady. The response stays predictable. Even in harsh industrial environments where other technologies struggle. And integration? Smooth. Automation systems accept the signal without drama.

From water management systems to complex process industries, hydrostatic level transmitters deliver dependable performance with long-term value. They don’t chase trends. They just work. When measurement truly matters, simplicity backed by physics always wins. That’s why hydrostatic technology continues to hold its ground as a practical, trustworthy solution for continuous level measurement in modern industrial systems.

Key Takeaways

- Hydrostatic level sensor technology measures level using direct pressure. Simple physics. Highly accurate. Continuous by nature.

- Hydrostatic level transmitters stay reliable even in harsh industrial environments. Heat, vibration, noise—it doesn’t faze them much.

- Installation is refreshingly simple. Works well in tanks, wells, and reservoirs without complicated setup.

- Strong long-term stability means less maintenance and lower operational costs over time. Fewer interruptions. Less worry.

- Ideal for industries that need dependable real-time level data without interference from surface conditions.

Want expert guidance on selecting the right hydrostatic level solution for your process. Call us at +91 8511104864 or email contact@rbautomate.com for detailed support and insights.

FAQs

What is a hydrostatic level sensor used for?

A hydrostatic level sensor is used for continuous liquid level measurement by sensing pressure at the bottom of a tank, vessel, or well. As the liquid level rises or falls, the pressure changes. The sensor reads that change and converts it into usable level data. Because this method relies on basic physics, it works extremely well in real industrial conditions. No fancy tricks. Just reliable measurement where it matters.

How accurate are hydrostatic level transmitters?

Very accurate, when chosen and calibrated correctly. These transmitters deliver stable, repeatable readings over long periods. Once set up properly, they don’t drift easily. That means fewer recalibrations, fewer surprises, and more trust in the numbers coming into your control system.

Can hydrostatic sensors work in dirty or turbulent liquids?

Yes, and this is where they shine. Foam on the surface? No problem. Turbulence, splashing, agitation? Still fine. Since measurement is pressure-based, surface conditions don’t interfere. The sensor focuses on what’s happening at the bottom, not the noise on top.

Is a hydrostatic water level sensor suitable for deep tanks?

Absolutely. Hydrostatic sensors are commonly used in deep tanks, borewells, sumps, and underground reservoirs. Depth doesn’t scare them. If the pressure range is selected correctly, they handle deep-level measurement with ease.

Why choose hydrostatic pressure level sensors over other technologies?

Because they keep things simple. Installation is straightforward. Maintenance stays low. Long-term stability remains strong. And performance stays reliable across a wide range of applications. When you need dependable real-time level data without unnecessary complexity, hydrostatic sensors are often the smartest choice.